We arrived early to set up the Armdroid display, and before we could finish unpacking everything we had a small crowd hovering around the desk.....

Above, Matthew (The Raspberry Pi Guy) was really taken by the Robotic arm, and wanted one! Ryan Walmsley was demonstrating his RTK-000-001 motor controller board & buggy, and some of the other demonstrations was equally as impressive!

Unfortunately, my Raspberry Pi was randomly rebooting itself, so out came the manual controller to the rescue !

Eventually the Pi started behaving itself.... Perhaps there was a shift in wind direction ?

I recompiled some of the test programs with shorter delay statements to speed things up, this made the arm appear a lot more responsive when controlled by the Pi.

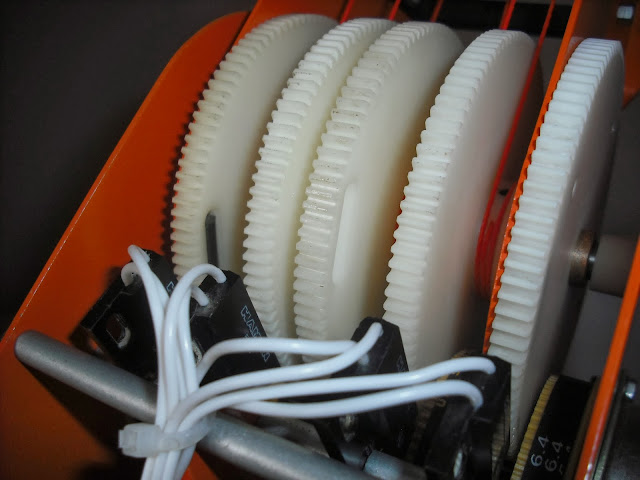

Daniel Bull was back with the mighty AstroBlaster arcade console... We spent most of the day talking (fantasying) about 3D Printing technologies. The question being... can we print replacement Armdroid components with enough precision not to require further machining ? We will have to wait and see...

Later in the afternoon I had the pleasure of meeting Gordon Henderson, author of Wiring Pi. This is the GPIO access library I've been using to write my Armdroid software.

I met lots of interesting people and wished I had taken more photographs.

I've been invited to the forthcoming Peterborough Raspberry Jam starting in March which I'm really looking forward to attend.

Final picture of the day.... Yulia and myself, ready for a well deserved Beer at a local pub ! It was after all a long and very successful day.

We suffered a breakage in the afternoon....

The tension equaliser had been playing up all day, and eventually lead to failure of the fingers. I suspect one of the retaining grub screws wasn't as tight as it should, this must have slipped. If you look closely at the Kevlar which didn't snap, literately tore itself free.

Actually, I couldn't have asked for a better proving ground - the kids absolutely loved playing with the Armdroid, and really gave it a good hammering... I've come away with a lengthy list of problems which need to be addressed & resolved for next time.

A full write up can be found at http://www.recantha.co.uk/blog/?p=7219 with an additional update http://www.recantha.co.uk/blog/?p=7290

Finally.... Big thanks to Michael and Tim, and all the Jam Makers for their superb organisation and dedication put into running such a good show. Next jam will be Saturday, 8 February.